Well, the clutch has never worked. That was one of the “disclosed” problems with this bike when I bought it. The other problems were all just extra surprises that I didn’t have to pay any extra for! I’ve been messing with this clutch off and on, and now it’s the only thing left between me and the open road, so now I have to tackle it.

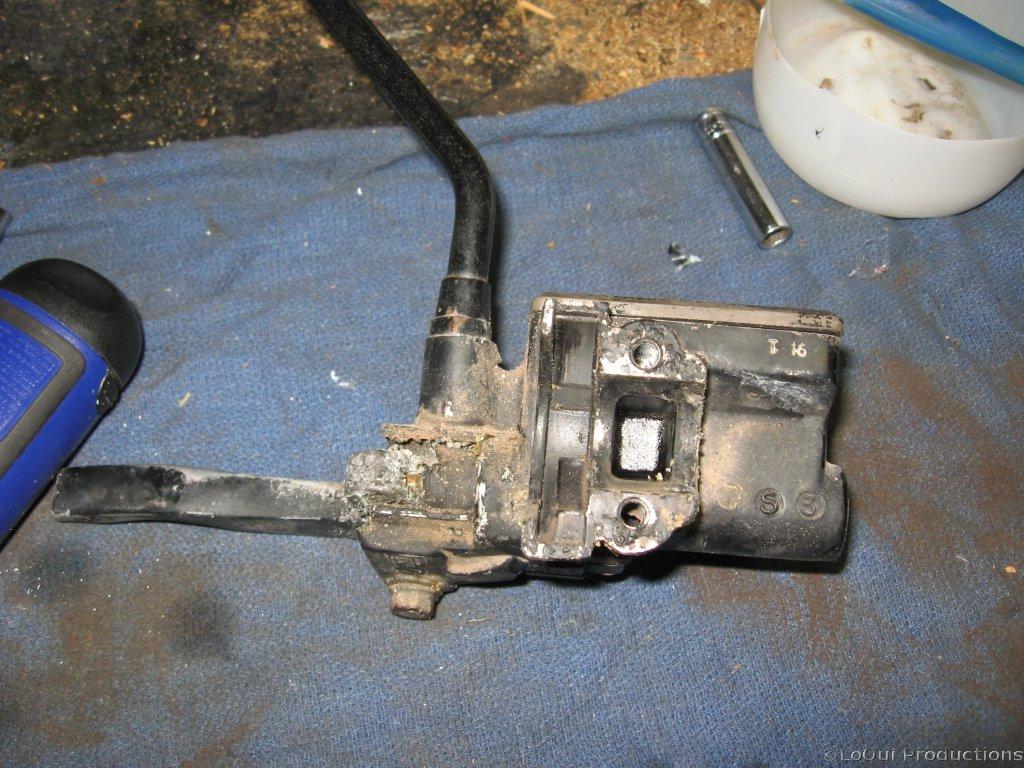

First off, I tried filling and bleeding the system with no luck. So, it’s time to dig into it. Upon visual inspection, I noticed the sight glass on the front of the reservoir is now weeping. I guess I didn’t notice this before because the system was dry. I checked the plastic sight glass with my top notch diagnostic tool (my thumbnail) and it went right through it. So I’ve got to find a way to keep the fluid from leaking out. I’ve noticed alot of these in the salvage yards have what looks like plumbers putty in them. I’m hoping to try something different, it may not work, so I’m also keeping an eye on eBay for a cheap master cylinder in better shape than mine. But more on that later.

So, time to drain the fluid, I used compressed air to force the rest of the fluid out of the line, and hopefully any gunk in the lines. It all came out clean, so I’ve got to assume the line is clean as well.

First to get the master cylinder off the bike, it’s pretty dirty and needs to be cleaned. Also need to remove the mirror and lever.

Remove the cap, and the bolt and nut that the lever pivots on. Pull the lever out, and the pushrod from within the boot and the piston. My boot is all torn to Hell so I’ll have to replace it along with all the other rubber bits.

Next I removed the clutch switch so it wouldn’t get damaged while cleaning. There’s just one screw holding this on.

I pulled the rubber boot out, and underneath that was a circlip holding this whole contraption together. Remove that, and the washer underneath it, and the piston should come out.

Next there’s a spring with a plastic cup to remove. This one wouldn’t just fall out but I could see the spring coils through the hole for the oil bolt, so I used a small screwdriver to start working it out. A gentle blast of compressed air got it the rest of the way out.

The bore that the piston came out of was full of crud. I didn’t have any Qtips long enough to reach the bottom, so I devised my own tool. I’m in negotiations with Sears Craftsman and Snap-On for the licensing rights 😉 Please don’t tell me they make longer Qtips, I don’t need to hear that. In any event, I got all the crud out. The reservoir, cylinder, piston, all shiny and gunk free. I also need to replace all the rubber bits and pieces. I’ve got them on order and will be rebuilding this next wknd.

**Update Do not attempt the epoxy fix below. It held up ok for a few years but it began to fail. Instead replace the old sight glass using the steps here.

Now for the sight glass. First I cleared out what was left of the plastic sight glass pieces and any leftover hydraulic fluid and cleaner. Then I took a penny, wrapped it in teflon tape, and wedged it up against the back of the sight glass from inside the reservoir. Next I laid the reservoir over so the sight glass area was horizontal. Then i filled it full of 2 part epoxy and set it up to cure. It’s been sitting over night and its still sticky, so I’ll leave it a while until it’s solid. I have no idea if this is going to work or not. The epoxy plug I’m making with this is straddling a ridge, so I don’t think it’ll pop out, but we’ll need to see if it’ll hold fluid or not. Like I said earlier, I’m keeping an eye out on eBay for a cheap master cylinder in case it doesn’t.

When the rubber bits come in next week I’ll rebuild this properly. Assuming my new sight glass holds fluid. For now I’ll start on the slave cylinder.